Mirka Power Lead – Correct Use and Handling Instructions

The Mirka power lead is designed with a safety release mechanism that must be used correctly when connecting and disconnecting the lead from the sander. Failure to follow the correct...

Mirka products are a perfect match for working with epoxy, whether you’re levelling, sanding, or finishing. The high-performance abrasives cut smoothly through hardened resin with minimal clogging, keeping the surface clear for precision work. Combined with Mirka’s ergonomic sanders and reliable dust extraction, you get faster, cleaner results and a flawless finish. With less mess and more control, Mirka makes sanding epoxy easier and more efficient.

Sanding wood and resin often creates clouds of dust that clog abrasives, spoil finishes, and pose health risks. Mirka’s dust-free solution, powered by Abranet mesh abrasives and efficient dust extractors, solves this by pulling dust away through the entire surface of the disc. The result is smoother sanding, longer disc life, and less time spent cleaning.

With resin especially—where fine particles can hang in the air and stick everywhere—Mirka’s system keeps the surface clear and the workspace safe. From timber slabs to epoxy river tables, you’ll get a cleaner process, sharper visibility, and a flawless finish without the mess.

The new Mirka DEROS II and DEOS II sanders are built for efficiency and comfort, helping you work smarter, not harder. Compact and lightweight, both models are designed with ergonomics front of mind—fitting naturally in your hand to reduce fatigue during long jobs.

The DEROS II packs a powerful motor and a low-profile design for precision and control, while the DEOS II’s slim, rectangular shape makes it ideal for corners and edges. With intuitive controls, consistent performance under pressure, and Bluetooth connectivity to the myMirka app, these next-generation tools deliver professional results with less effort.

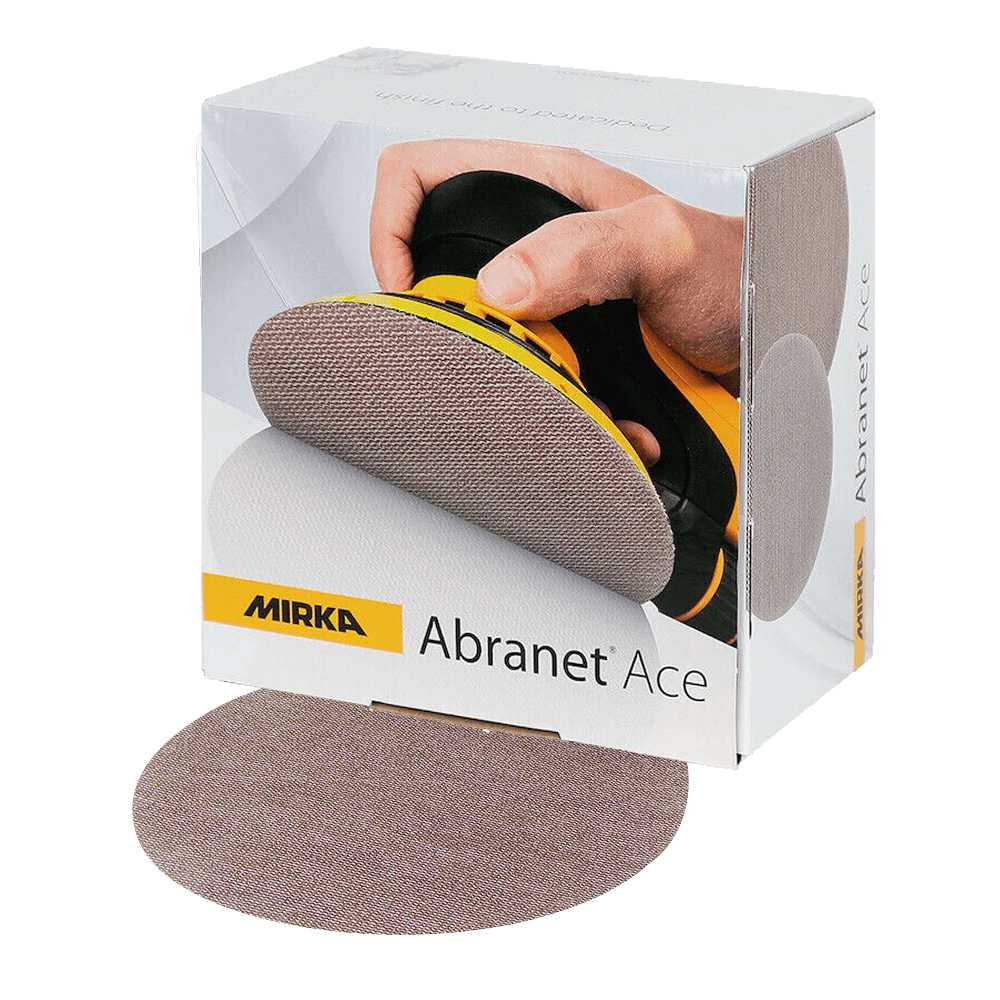

Thanks to the optimized net construction and ceramic grains, Abranet Ace offers superior cut and performance for hardwoods (such as beech and oak) and fast cutting on various solid surface materials as well as for cleaning of different industrial rollers. Abranet Ace also works excellent on primer sanding applications.

Tough on hard surfaces

Mirka Abranet Ace HD 150mm Ceramic Discs delivers exceptional performance and durability.

Designed with advanced ceramic net abrasive technology, it excels in heavy-duty tasks, including working on hard surfaces like resin, hardwood, composites, and stripping paint or lacquer.

Its unique diamond-pattern net construction combines outstanding strength with a dust-free sanding experience, ensuring maximum efficiency and longevity.

Making a Dark Coloured Epoxy Table

This process shows an overview of how to make a dark coloured epoxy table. As different epoxy products are mixed to different ratios and have different instructions, we didn't include any technical information.

Step 1: Moulding

Step 2: Pouring

Step 3: Sanding

Step 4: Finishing

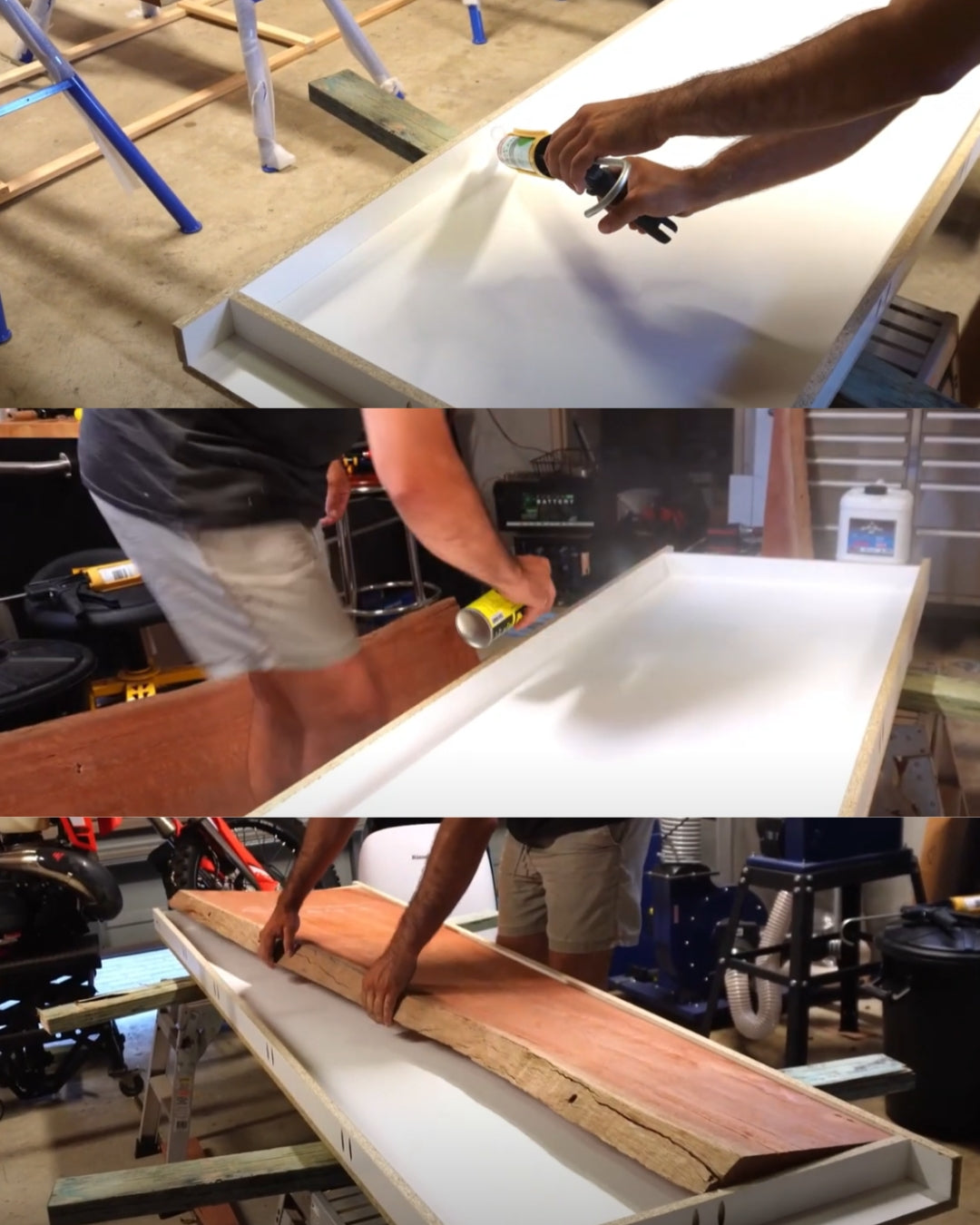

Making a Light Coloured Epoxy Table

This process shows an overview of how to make a light coloured epoxy table. As different epoxy products are mixed to different ratios and have different instructions, we didn't include any technical information.

Download ProcessStep 1: Sand with Galaxy

Step 2: Sand the Resin

Step 3: Wet Sanding

Step 4: Polishing

Step 5: Finishing

The Mirka power lead is designed with a safety release mechanism that must be used correctly when connecting and disconnecting the lead from the sander. Failure to follow the correct...

At Elite Fibreglass, quality isn’t just a goal — it’s the standard. With over 30 years of combined experience in the marine and fibreglass industries, Dale and Chris have...

At Mirka Australia, we’re excited to introduce the POLAROS RP 600 Rotary Polisher — a bold reimagining of what a professional polishing tool can be. Designed with forward-thinking features, outstanding performance,...