Why I’m Switching to Mirka: A Furniture Maker’s Demo Experience

When Ben, a skilled furniture maker known for his craftsmanship, recently put Mirka tools through their paces, he was struck by how much easier and more enjoyable sanding could be....

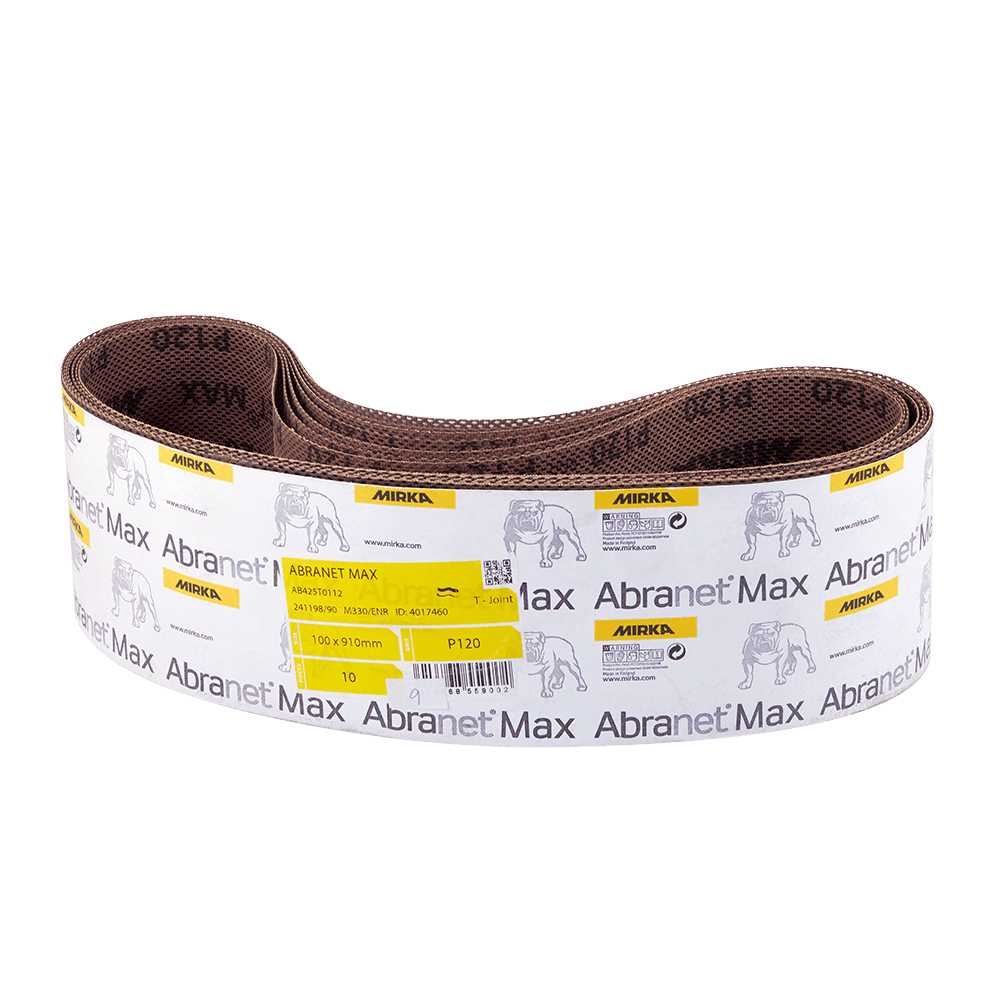

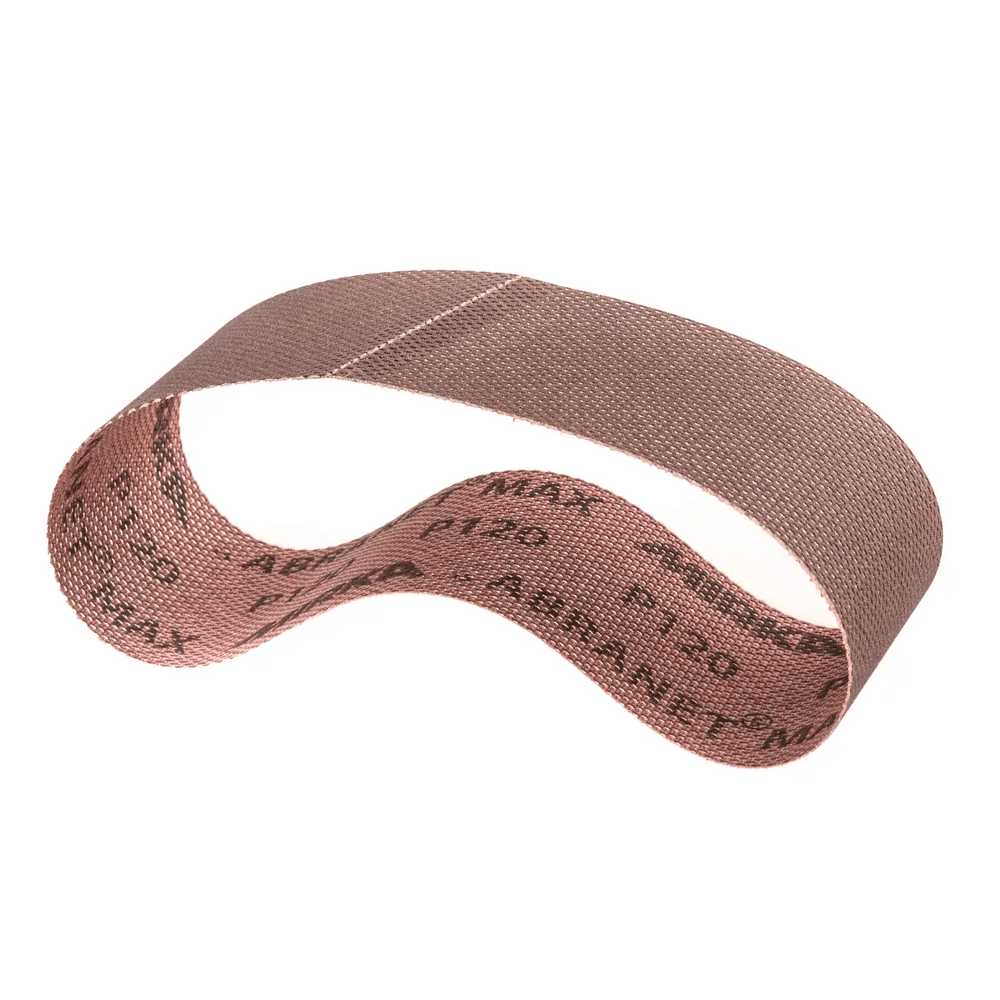

Abranet Max

Aluminium Oxide

Abranet Max is a durable net abrasive ideal for wood sanding, resisting clogging on resinous or soft materials while keeping surfaces cool. Its tough aluminum oxide grain ensures a high cut rate, long lifespan, and reduced belt changes, saving both time and costs.

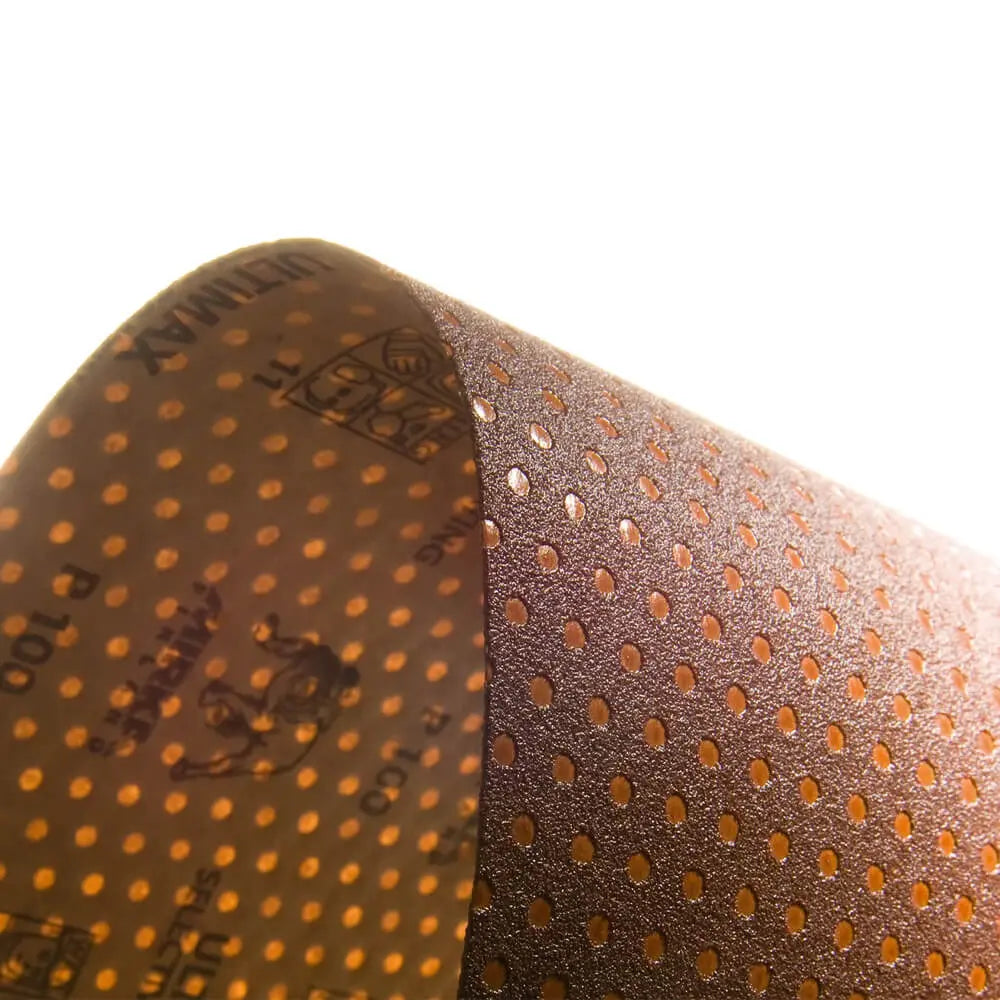

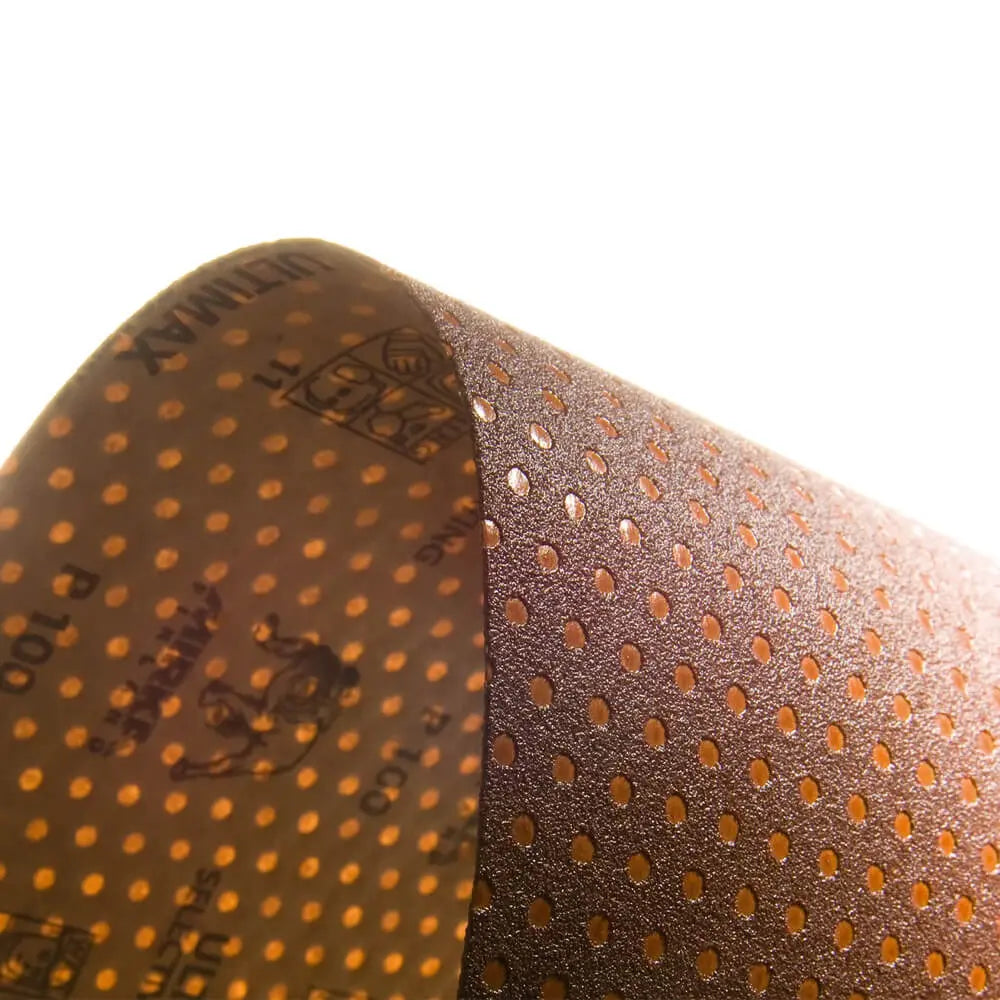

Ultimax

Aluminium Oxide

Ultimax combines cutting-edge design and technology to deliver maximum performance and efficiency while keeping costs low. Its innovative Selective Coating™ Technology sets it apart, ensuring superior sanding results with reduced waste and longer lifespan.

Ultimax Black

Silicon carbide

Mirka Ultimax Black is a long-lasting, antistatic sanding belt with strong backing and silicon carbide grain for high stock removal and reduced clogging. Its cooler sanding process prevents burn marks, while durability minimizes belt changes, saving time and costs. Available in various sizes and grits, it’s ideal for wood and composite materials.

Increase profit

Overall sanding costs can be minimised simply by choosing the most suitable

product for each sanding operation. That means:

Choosing the right type of grit and coating

Using the optimal grit sequence

Avoiding sanding with finer grits than necessary

Sand longer

The lifespan of the belt can be prolonged by ensuring that the sanding equipment is correct and used properly.

Choose the right type of sanding unit for each sanding operation

Adjust the sanding machine correctly

Ensure the machine is properly maintained

Check that the dust extraction is adequate

In general, the first sanding belt is used for stock removal, while the following belts are only used for creating an even surface finish.

Typically, the first sanding unit consists of a drum made of materials such as steel or hard rubber. The drum, in combination with coarse grit (P36–P100) belts, is ideal for efficient stock removal. When it comes to producing an even surface finish, sanding units that incorporate soft rubber drums or sanding pads are normally used. In these units the grit range varies from P120–P320. For sanding between coats or intermediate sanding, grits P320–P800 are most commonly used along with a very soft rubber drum or a soft sanding pad.

When choosing a grit size the recommendation is to select belts that are only one step from each other in grit sizes. For example, P80–P120–P180 are appropriate steps, whereas P60–P120–P220 often results in problems with the surface finish and product lifespan.

In general, the first sanding belt is used for stock removal, while the following belts are only used for creating an even surface finish.

P24-P80: Coarse sanding, calibration

100-P220: Sanding before coating

P220-P500: Intermediate sanding

P600-P1200: Pre-polishing sanding

Download this guide to find out which belt abrasives are best for the type of sanding you will be doing, and what substrate you will be sanding.

We currently have some Belt sizes available in the following brands: Hiolit Xo, Ultimax, and Abranet Max, but now you can get Abranet Max, Ultimax and Ultimax Black cut to size!

Grant BraceI required a sanding belt of an unusual length for my linishing machine not available in Australia. A woodworking products outlet recommended that I call a company, Best Abrasives. To my amazement, Ryan and his team were ultimately able to source this bespoke product which can be made in virtually any size sanding belt. This is just outstanding service. Thanks to the team at Best Abrasives.

Grant BraceI required a sanding belt of an unusual length for my linishing machine not available in Australia. A woodworking products outlet recommended that I call a company, Best Abrasives. To my amazement, Ryan and his team were ultimately able to source this bespoke product which can be made in virtually any size sanding belt. This is just outstanding service. Thanks to the team at Best Abrasives.

Same day dispatch

Orders received by 2pm AEST are dispatched on the same day, with express post options Australia-wide.

Outstanding Service

Contact our helpful team at info@bestabrasives.com.au

or by phone on 02 8036 8478.

100% Australian

Best Abrasives is 100% Australian owned and operated.

When Ben, a skilled furniture maker known for his craftsmanship, recently put Mirka tools through their paces, he was struck by how much easier and more enjoyable sanding could be....

In painting, prep work is just as crucial as the finish — and having the right sanding gear can make a massive difference to your efficiency and final result. Rhys...

Using Mirka abrasives? Good call. Want to make them last even longer? Here are 11 practical tips to help you save money, reduce waste, and get more out of every...